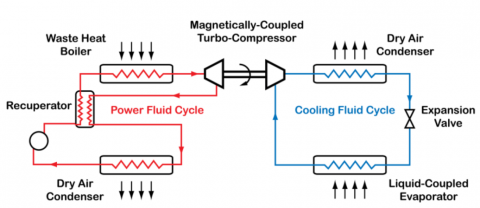

| Billions of gallons of water are evaporated each year at electric power plants in the U.S. for cooling purposes. As freshwater resources become strained in the U.S. and the rest of the world it is of great interest to find alternative dry air cooling approaches. Standard dry air cooling requires equipment that is very large, expensive and has poor efficiency. Barber-Nichols Inc. (BNI), Colorado State University (CSU) and Modine Manufacturing Co. won a DOE ARPA-e award in 2016 to design, build and test a highly efficient supplemental cooling system that uses low-grade waste heat at power plants (see figure 1). This technology promises to significantly reduce the size and cost of dry air heat exchangers in power plants while increasing overall efficiency and reducing water footprint. |

|

| Figure 1 – Figure from CSU paper titled “Ultra-Efficient Turbo-Compression Cooling” |

| For this innovative system, BNI will design, build and test a magnetically coupled turbine-driven compressor. To optimize efficiency in the system it is advantageous to use different fluids for the expansion and compression systems. The magnetic coupling allows for a single machine operating between these two systems to be hermetically sealed and optimizes transmission efficiency (see figure 2). This particular design will push the limits of current magnetic coupling technology as the machine will rotate at a target speed of 30,000 rpm while transmitting power of approximately 12 kW. A non-metallic barrier can is used between the magnetic half couplings to minimize losses from operating at this extremely high speed. |

|

| Figure 2 – Refrigerant Schematic of System from CSU |

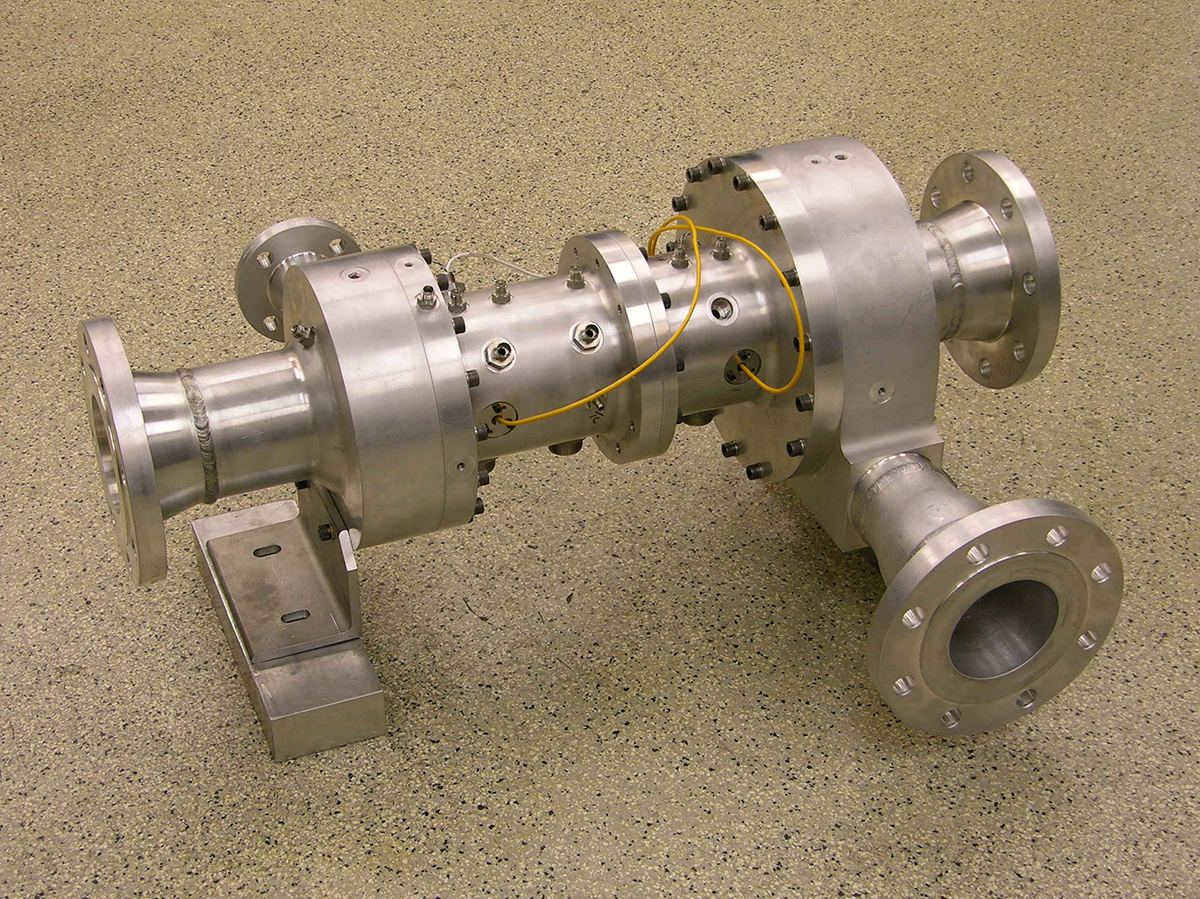

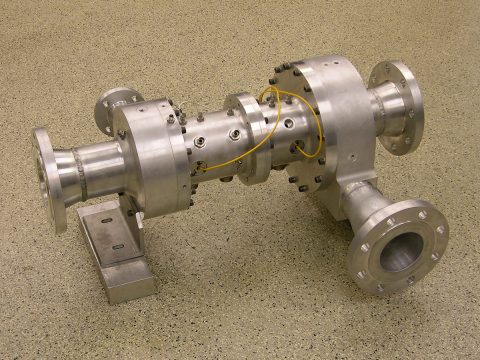

| BNI has finished manufacturing all of the parts for this turbocompressor and is currently assembling these components to get ready for initial spin testing at its Arvada, CO facility in December 2017 before shipment to CSU by the end of the year (see figure 3). Full up system testing will take place at CSU in Fort Collins, CO in early 2017. |

|

| Figure 3 – Turbcompressor Housings Assembled Following Successful Hydrotest |