Barber-Nichols has been integrally involved in the development and evolution of radar and directed energy (DE) thermal management systems for multiple types of configurations and topologies including a very broad range of cooling fluids. Complimentary to Barber-Nichols’ industry-leading cooling pumps are complete Thermal Management System (TMS) design and simulation, including transient analysis and control.

Thermal Management Solutions

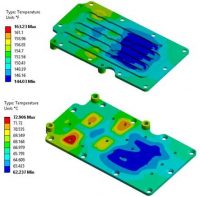

Thermal Management System Analysis

BN has proven analysis tools and expertise to model complicated thermal management systems with multiple variables and find optimum solutions for pumps, heat exchangers, piping, valves, etc. for a wide range of thermally challenging applications. BN also has in-house capabilities to design and build state-of-the-art additive manufactured heat exchangers.

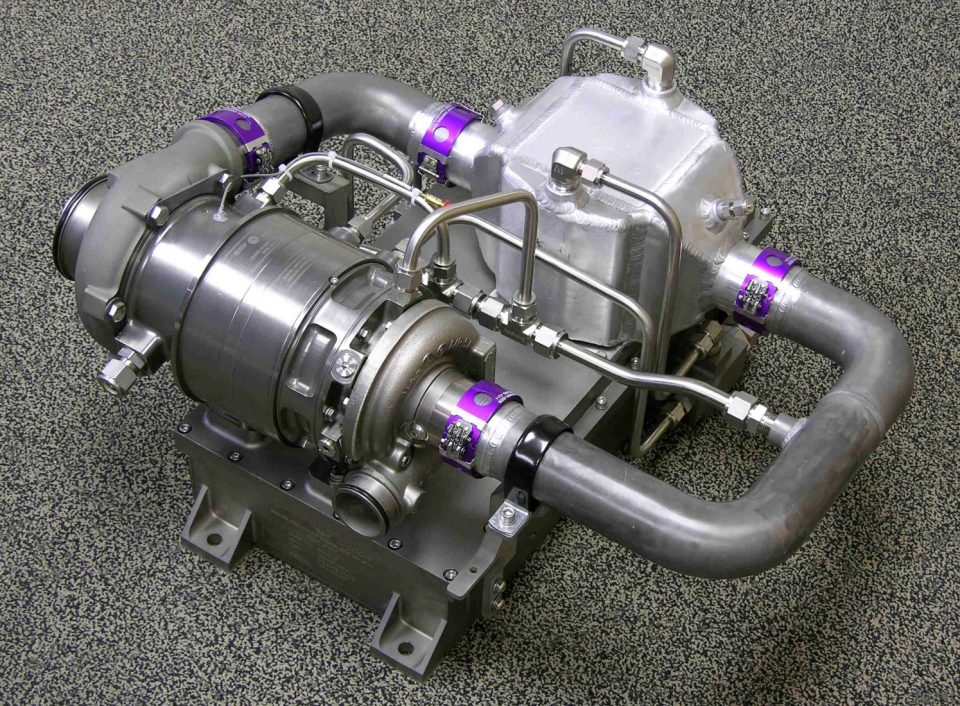

Two Stage Compression System

In applications where multiple stages of compression are needed, it is advantageous to cool first stage discharge gas prior to entry into the second stage. This photo shows a highly efficient heat exchanger integrated with a two-stage compressor and controller for an aircraft application.