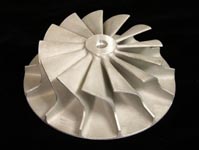

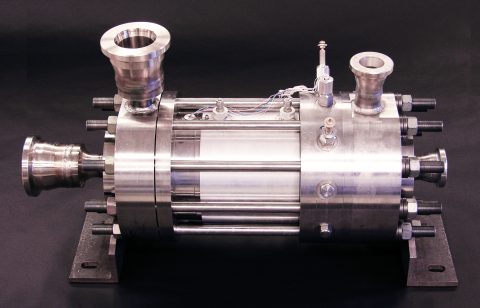

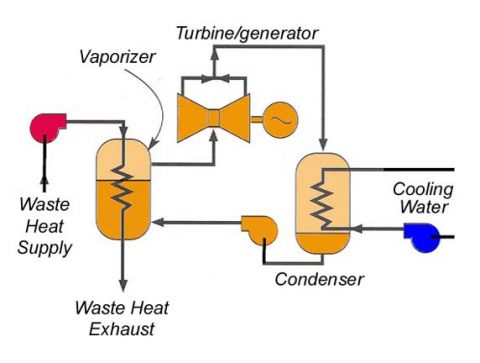

Turbines are used to capture the kinetic energy of a working fluid such as water or steam and convert that energy into rotational motion that can be used to drive other types of equipment. Some more common applications include commercial power generation, rocket engine turbopumps, and torpedo propulsion. Barber-Nichols (BN) has over 50 years of experience designing and manufacturing a wide range of single and multistage-stage turbines which include:

– Inlet temperatures from cryogenic to 1,370 °C (2,500 °F)

– Power levels from Watts to megawatts

– Rotational speeds exceeding 400,000 rpm

BN possesses the necessary tools to design the turbine that is most appropriate for your system, as well as the manufacturing capabilities required to take each design from concept to reality. These skills have produced hundreds of clean sheet turbine designs with most resulting in tested hardware.