Since 1976, when Barber-Nichols designed and manufactured its first cryogenic pump, these custom-manufactured and engineered products have found their way into a broad range of demanding and sensitive applications. These include cooling of superconducting cables for power distribution systems, cooling of synchrotron x-ray crystals, cooling of superconducting magnets, circulation of a supercritical cryogenic nuclear moderator, circulation of cryogenic propellants within launch vehicles, and transfer of cryogenic liquids in industrial and propulsion applications. Check out more examples of our cryogenic turbomachinery.

Cryogenics

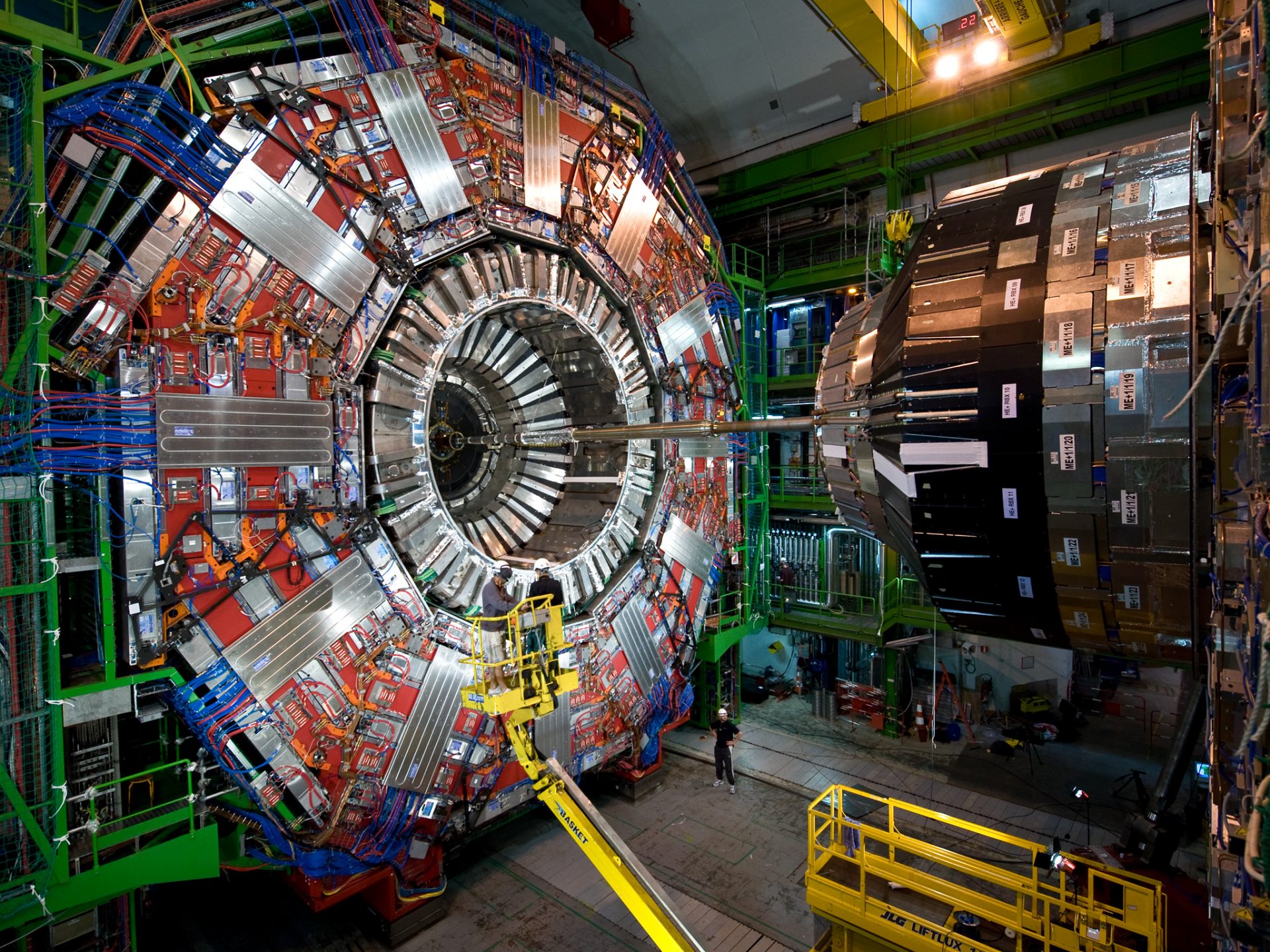

Circulation of Liquid Helium in CERN's ATLAS Detector

Barber-Nichols helium pumps are being used at the CERN ATLAS detector to pump liquid helium coolant through superconducting magnetic coils. These helium pumps are some of the world’s largest, each circulating 1.2 kg (2.6 lb) of liquid helium per second at 4.5 K. The ATLAS Detector came to fruition through the collaboration of 1,800 people from 34 countries and will help physicists more accurately understand the nature of matter and the forces that shape the universe.

Liquid Argon Circulation in Support of Neutrino Research

Barber-Nichols designs and manufactures cryogenic pumps for ultra-pure cryogenic systems including those used for physics research. Working fluids include liquid argon, krypton, neon, and xenon. Barber-Nichols designed and manufactured several liquid argon pumps and a cold argon gas blower to support Fermilab’s ProtoDUNE, a precursor to the full-scale DUNE program. These machines circulate the liquid argon through the detector tank and cryogenic systems which purify it and keep it cold. High purity is of utmost importance for physics applications that rely on extremely sensitive instruments to detect some of the smallest known particles.

Barber-Nichols' Supercritical Hydrogen Circulator for the Oak Ridge National Laboratory's Spallation Neutron Source

BN designed and manufactured a supercritical hydrogen circulator for the Oak Ridge National Laboratory’s (ORNL) Spallation Neutron Source (SNS). The SNS produces high-intensity neutron beams that are used to investigate how materials are assembled at the subatomic level. The SNS utilizes a hydrogen loop system to cool the neutrons; it begins operation at room temperature and then cools down to 17 K (-429 °F). A Variable Frequency Drive was used to adjust speed to meet the required performance range.

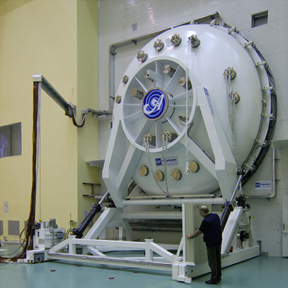

Barber-Nichols' Nitrogen Gas Circulator in Space Simulation Chamber

Barber-Nichols is the world’s leading supplier of high-speed nitrogen gas circulators used in satellite test chambers. Barber-Nichols’ blowers circulate nitrogen gas between (422 K [+300 °F] and 89 K [-300 °F]) for months at a time so satellite electronics can be tested properly prior to launch.