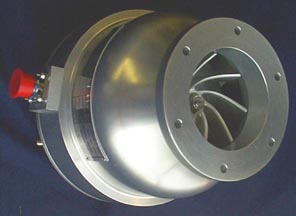

Barber-Nichols (BN) has the experience to design, produce, and test aerospace compressors and fans for your most demanding applications. BN can design custom, or modify existing, compressors and fans to accommodate a wide variety of applications. Compressors and fans are conceptually designed using Meanline and streamline software. BladeGen® is then used to generate the three-dimensional blading and CFD Analysis is used to optimize the blade design for performance and noise reduction. BN utilizes Stereolithography (SLA) generated investment castings and/or five-axis machining to rapidly and cost-effectively produce prototypes. Some of the most demanding applications required small and/or lightweight fans with:

- Discharge Pressures Reaching 61 cm (24 in) of Water

- Tip Speeds Reaching 333 m/s (1,100 ft/s)

- Volumetric Flow Rates Reaching 23,786 m3/hr (14,000 ACFM)